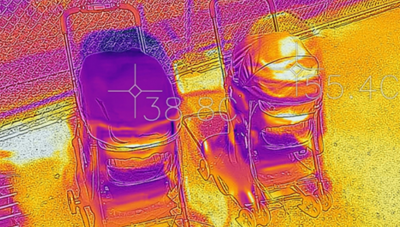

For cooling, saving, comfort improving & environmental protection The Radi-Cool radiative cooling meta material features a high solar reflectivity and a high infrared emissivity across the atmospheric window. When applied onto an object on the Earth, it establishes an effective radiative heat transfer channel between the object and the cold Universe. Without consuming electricity, the meta material cools objects even under direct sunshine. Applied to the Cooling Fabric According to the application field of end products, there are several types of Cooling Fabrics: 3.1 Taffeta Cooling Fabric recommended to make: parasol, cap, hat, sunshade cloth, etc. 3.2 Oxford Cooling Fabric recommended to make: car cover, tourist tent, sunshade cloth, etc. 3.3 Polyester Elastic Cooling Fabric recommended to make: rolling curtains, skylight curtains, sunshade cloth, fisherman hat, etc. 3.4 Polyester Low Elastic Cooling Fabric recommended to make: sunshade like garden umbrella, beach umbrella, etc. Radi-Cool Fabric Thermal Image

view more

Sorona Fiber/ Fabric Introduction Since the Second Industrial Revolution, human's industrial modernization level has been promoted rapidly, and the global economy has entered a new era, with economic growth far higher than any previous era. The reason cannot be ignored is that human began to use fossil fuels on a large scale, including but not limited to coal, oil and natural gas. The burning and use of large amounts of fossil fuels will inevitably produce huge amounts of greenhouse gases. The textile industry accounts for about 10% of global greenhouse gas emissions each year. Therefore, the sustainable development of the textile industry will bring positive changes to the earth's environment. The Definition of Sorona Fiber Sorona is a kind of fiber fabric introduced by DuPont. It is widely used in the production of textile clothing and other household and commercial carpets. Sorona polymer is made up of 1, 3 - propanediol (PDO) and PTA (DMT) or the two primary ingredients. Among them, PDO is the key raw material, accounting for 37% of the total raw material. The environmental protection of Sonora Fiber The production by using the biochemical SORONA polymer has the following three environmental value: 1. 37% of its feedstock comes from natural renewable sources rather than from petrochemical sources, thereby reducing its dependence on oil resources; 2. The same output Sorona polymer, compared with the nylon polymer based on petrochemical raw materials, Sorona USES 30% less energy than the latter in made. 3. The same output Sorona polymer, compared with the nylon polymer based on petrochemical raw materials, Sorona made in carbon dioxide emissions 63% less than the latter. Sorona fiber manufacturing process Sorona Fiber/ Fabric Features 1. Soft feel of fabric, low modulus of SORONA, larger deformation under the same force, so the fabric woven by SORONA has a soft touch. 2. atmospheric pressure boiling dye easy dyeing, gorgeous lasting color. SORONA fiber has excellent dyeing performance and bright color, the best dyeing temperature is 100℃, about 30℃ lower than ordinary polyester, and SORONA fiber dyeing depth is high. 3. with resistance to chloride/uv and anti fouling characteristics of easy do. SORONA fibers have a low yellowing degree with increasing temperature and can withstand harsh chemical treatments. 4. comfortable stretch and resilience, SORONA fiber with high elasticity and low elastic elongation, elastic more durable than other normal elastic fibers, elastic fabrics can reach 20%, with comfortable elasticity. The morphology of spandex fibers under the microscope The morphology of Sorona fibers under the microscope The Application of Sorona in Clothing Sorona Workwear Fabric (1) Comfort, the workwear fabric made of Sorona® fiber is flexible. It can fit the movement of the body, stretch freely, and then recover the original state naturally. (2) Sorona ® fiber can keep fabric appearance persistent , bright colors, and out of shape not easily; Plus, the workwear looks like it's just been washed and pressed, thanks to Sorona® fiber's restorative anti-wrinkle properties. (3) quick drying, Sorona ® fiber workwear clothes in the same conditions can have more than any other fiber twice as fast drying speed. Sorona Outwear Fabric Sorona® enables outerwear to possess a unique property, the ability to "morphological memory". Morphological memory means that our customers can remove wrinkles from the fabric with a simple shake when they take out a jacket from an overstuffed suitcase -- a unique feature that makes your Sorona® jacket ideal for the fast living consumer. With Sorona®, just a little shake and the trench coat will be as flat as if it had just been ironed. Sorona Performance Fabric (1)High color fastness. Sorona® has comfortable elasticity and good color fastness, able to maintain bright color. It is the ideal functional fabric for outdoor sportswear. For consumers, functional fabrics made with Sorona® can avoid fading due to intense UV exposure and can be washed repeatedly, extending the life of clothing. (2) For fabric factories, garment manufacturers and designers, Sorona ® is one of the most outstanding feature can improve the performance of other fibers. For a variety of functional fabric flexibility to provide advantage, different types of outdoor activities for clothing function also is not the same.

view more

What is Yarn Dyed Fabric The dyed yarns are generally divided into two ways: colored spinning and dyed yarns. Generally speaking, the yarn-dyed fabric refers to the cloth woven by the shuttle loom, but the knitting machine can also make yarn-dyed knitwear. Compared with printed and dyed cloth, it has a unique style, but the price is more expensive. Because the total loss of dyed yarn, weaving and finishing of yarn-dyed cloth is relatively larger, while the output per machine is not as high as that of white grey cloth, so the cost increases. Product Features Compared with conventional products, yarn-dyed fabrics have better color fastness because they are dyed first and the color penetrates into the yarn, while printed and dyed fabrics usually have areas where the yarn is not colored when you peel the yarn. Minimum order quantity is small. No matter what yarn weave, density, grain, color tens of meters and hundreds of meters can also be done, but it is difficult to customize the dyed printed fabric without grey cloth, and the dyeing and printing process will limit the small batch production. Full Yarn Dyed Fabric Dyed or partially dyed yarn in both warp and weft (or fabric with several colored yarns interwoven with white yarns. Semi Yarn Dyed Fabric Warp or weft yarns are dyed or partially dyed. Blank yarn can not be used to weave yarns. Because the tension and shrinkage of the blank yarn is different from that of the dyed yarn, it must not be used in the warp direction, and when used in the post-finishing of the latitude direction, the cloth surface will be deformed because of the shrinkage problem. So generally colorless yarn is half - drift or full drift treatment. Advantages of Dyed Fabric Compared with printed and dyed cloth, yarn-dyed cloth has the characteristics of rich color, strong stereotyping and high color fastness. However, due to the larger losses in dyeing, weaving and finishing processes, and the higher output of production than white grey cloth, the input cost is higher and the technical requirements are higher. Yarn-dyed fabric accounts for only 7% of the global cotton spinning industry, with the highest proportion of printed and dyed cloth and denim. In the future, with consumers' demand for clothing colors becoming more fashionable and changeable, yarn-dyed fabric still has great prospects for development.

view moreNo.2288,The 3rd Nanhuan Road,Shengze,Wujiang,Jiangsu,china.

0512-63599999